Loadcenters and Panelboards

Primer Basic NQ Panelboard

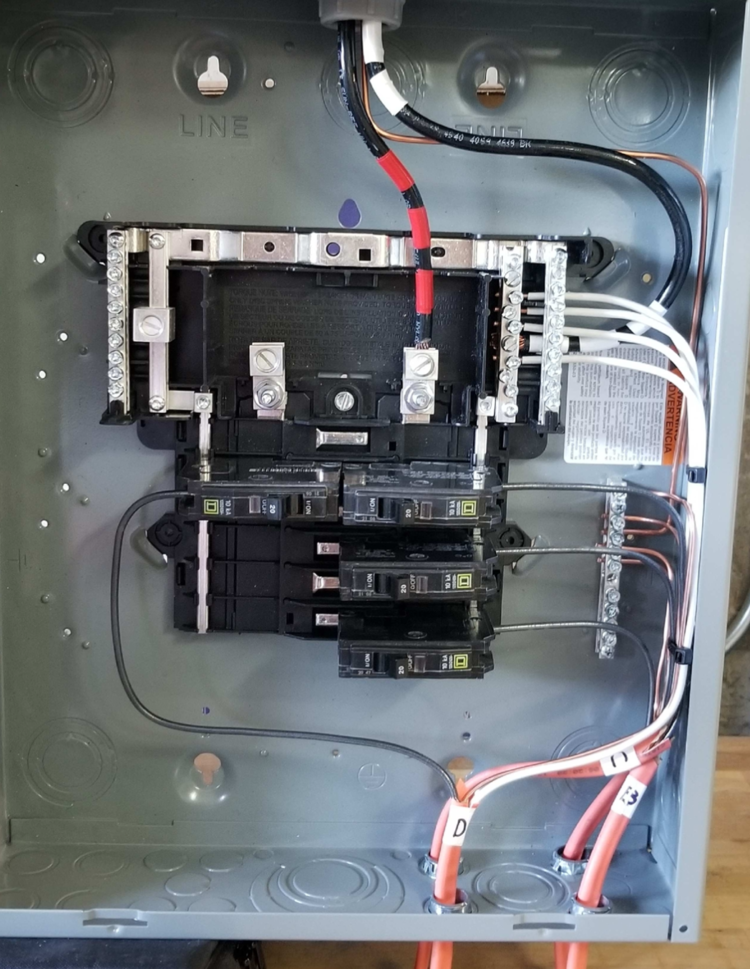

The most basic panel I offer is completely stock. As from the Distribution warehouse. I gather the correct parts and do basic assembly which may consist of installing breakers and SPD where they are optimally positioned and wired in.

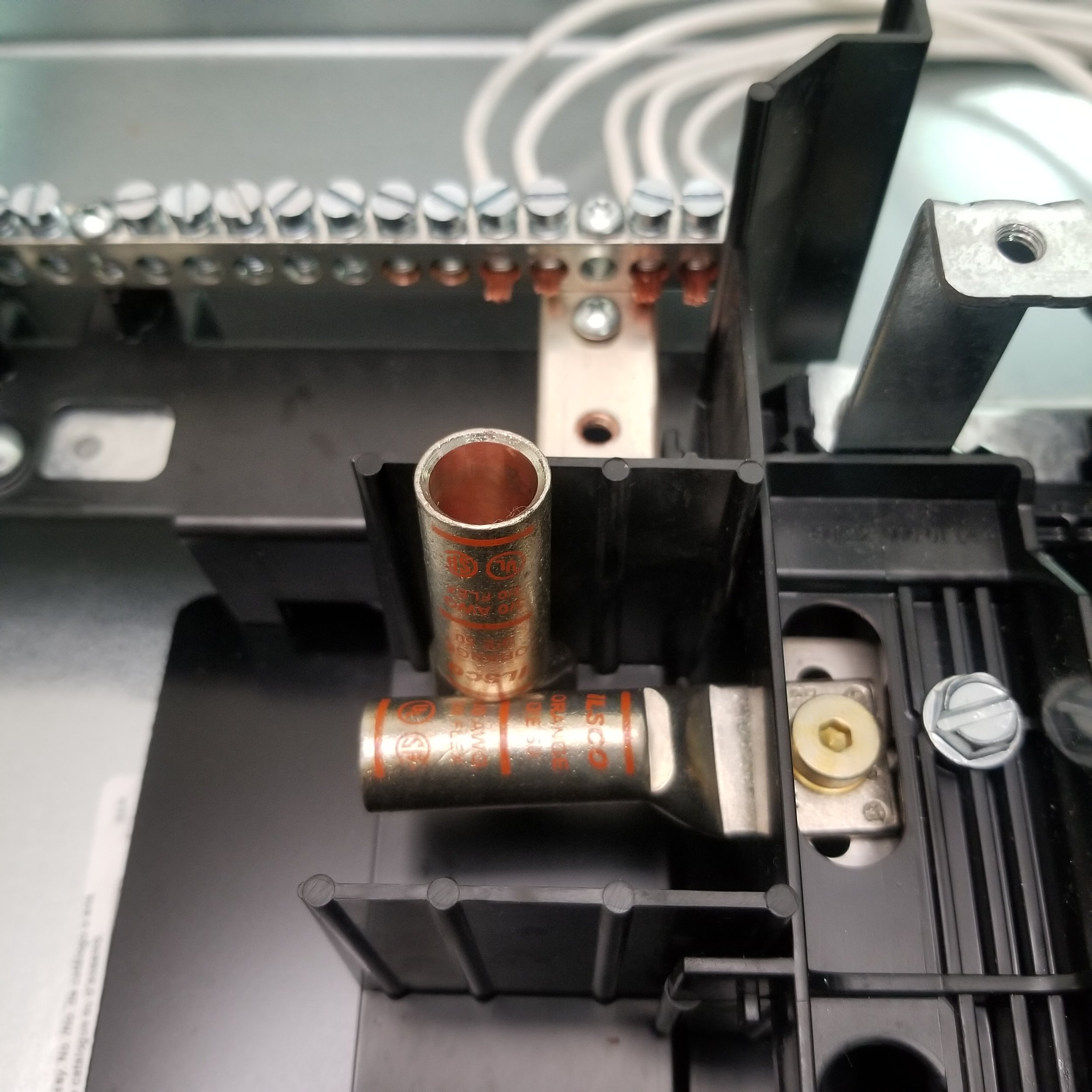

I will remove the aluminum service lugs and loosely place the appropriate copper compression lug for installation in the field.

I will use contact enhancers and wipe surfaces when doing this work. But I will not dissassemble any componants.

With this type of service, it is generally easier to have the installing contractor procure the can and cover from a local distribution warehouse. They are generally readily available. This greatly reduces shipping cost. Shipping a cover and can is about $250. Shipping just an interior is about $125. A 100A or 225A main lug only panel, stock is $1250 plus breakers and spd. Contractor provides can and cover. Estimated cost cover and can is $375.

Options

I also offer an option where I can engage in a variety of activities to bring these panels higher in ability to pass less restricted electrical current with cleaning and mild polishing. All this affects the price of the panel as well as the UL rating of the panels.

Cleaning vs Reconditioning

If I am to take apart a panel and remove any burs and polish/Anti-oxidize surfaces of machining oils and oxidation, I call it cleaning. Some people may call it Reconditioning. Cleaning would be NEC compliant. Reconditioning would not. Cleaning and light polishing of contact surfaces without removing any plating metals is in my mind, safe and still produces a NEC compliant product. Some installers won’t allow it and site NEC 408.8. If that is the case, you can still use a Basic Panel that has listed and labeled parts that have never been altered. A Basic Panel is still a far superior panel to a SQD QO or Eaton CH loadcenter on many levels. They are far more robust and can be configured with copper components. And the plating on the bus is silver with nickel on the branch fingers. Loadcenters are tin plated copper bus with aluminum neutrals and grounds. There is small apparent sonic impact between aluminum and copper junctures. Aluminum adds a sleigh veil and haze.

Damping of panels. I like to coat the can and the support rails on the NQ panelboards. There is a lot of ringing in them. I see no reason an inspector would question vibration material on a panel can. At times we have to coat a panel can with fire putty to meet building code.

Cleaning/Deoxing a Panelboard

I wanted to touch on what this really means.

Using corrosion dissolving and protective compounds. When you touch a part with a D series of Deoxit a chemical reaction occurs. You break down existing oxidation and manufacturing oils on the surface. Deoxing does not stop there. Now you have a mess of pollutants suspended in the Deoxit, sitting there. You have to remove it. This means your hitting a piece of metal 4 or 5 times till you have really lifted and wiped the contaminants from the surface of the material. Next you have to change formula and do it again. This time it will only take 2 to maybe 3 passes. Its very time consuming and tedious work. But it results in an extremely low O2 free contact surfaces between parts. That means you have severely retarded oxidation time in the future. Parts remains very low impedance with less noises. I hear 10 to maybe 15 years. I would personally tell people to use a small 2 oz spray in panels every 5 years to keep them fresh. if your in a salt environment, every 2 years or more. I provide directions on maintenance if people ask.

Panel Options

I have refined my selection down to 2 power panels. These panels are all steps above the readily available load centers installed in residential homes. These panels are all UL listed and labeled. These panels all meet the intent of the National Electrical Code (NFPA 70, NEC). They are all made in the USA. Some circuit breakers originate from other countries. Generally Mexico if not the USA.

Our panels can be designed as a replacement for a main power panel, or as a subpanel.

What makes our panel better

When considering a panel, you have to consider the whole of the electrical infrastructure. What are you trying to do. Are you installing a main panel? Are you replacing a main panel? Are you adding a subpanel? Are you adding a premium subpanel? Much of what we offer with our design service is establishing performance goals for the audio system, while at the same time, giving clear advice on how best to control cost. Where is the biggest band for the buck.

We have studied panels and breakers for a long time. We understand the difference between a load center and a panelboard. They are different.

Residential loadcenters - These panels are designed to supply power to most every residential home that utilize circuit breakers designed to meet 210.12(AFCI). Loadcenters are generally fabricated out of aluminum bus materials. A step up in quality is available with tin plated copper phase bus material. Copper neutrals and grounds are not available for loadcenters. They are all aluminum. They are made to a minimum standard. They are mass produced at the lowest price possible using inexpensive lightweight material. They work very well to their intended purpose. Powering general purpose outlets, lighting and other devices used around a home.

If your electing to use a loadcenter which is fine, they can be acquired by the installing contractor. There is still a very particular way in which to land the feeders and terminate the branch wires. I can assist in providing a spec and installation guidelines for the installing electrician.

Panelboards, Utility service equipment - Square D NQ Panelboards are for commercial/light industrial use and can be configured with copper phase, neutrals and ground bus. All UL Listed and Labeled.

Panelboards can utilize bolt on or plug on QO circuit breakers. Panelboards utilize better interior metal. They are built with robust copper bussing. Think ⅛” x 1.5” phase bar material. Because their interior metal phase bars are more robust with silver plated copper, they are an excellent selection when powering an entire residence or business. They have massive current delivery capability. They are designed specifically to handle loads such as 60A rapid car chargers, oven, HVAC, solar, battery backup, generators, pools, subpanels etc.

They are an excellent source to feed audio and video directly from.

Please note, panelboards only come in a 20” wide configuration and require 2x6 framing to meet its depth requirements. This is not an issue with new or remodel construction where drywall is not in place. Even if the panel is being used in a remodel, a stud can be cut and the panel screwed to the top and bottom of the cut stud. This is a legal install.

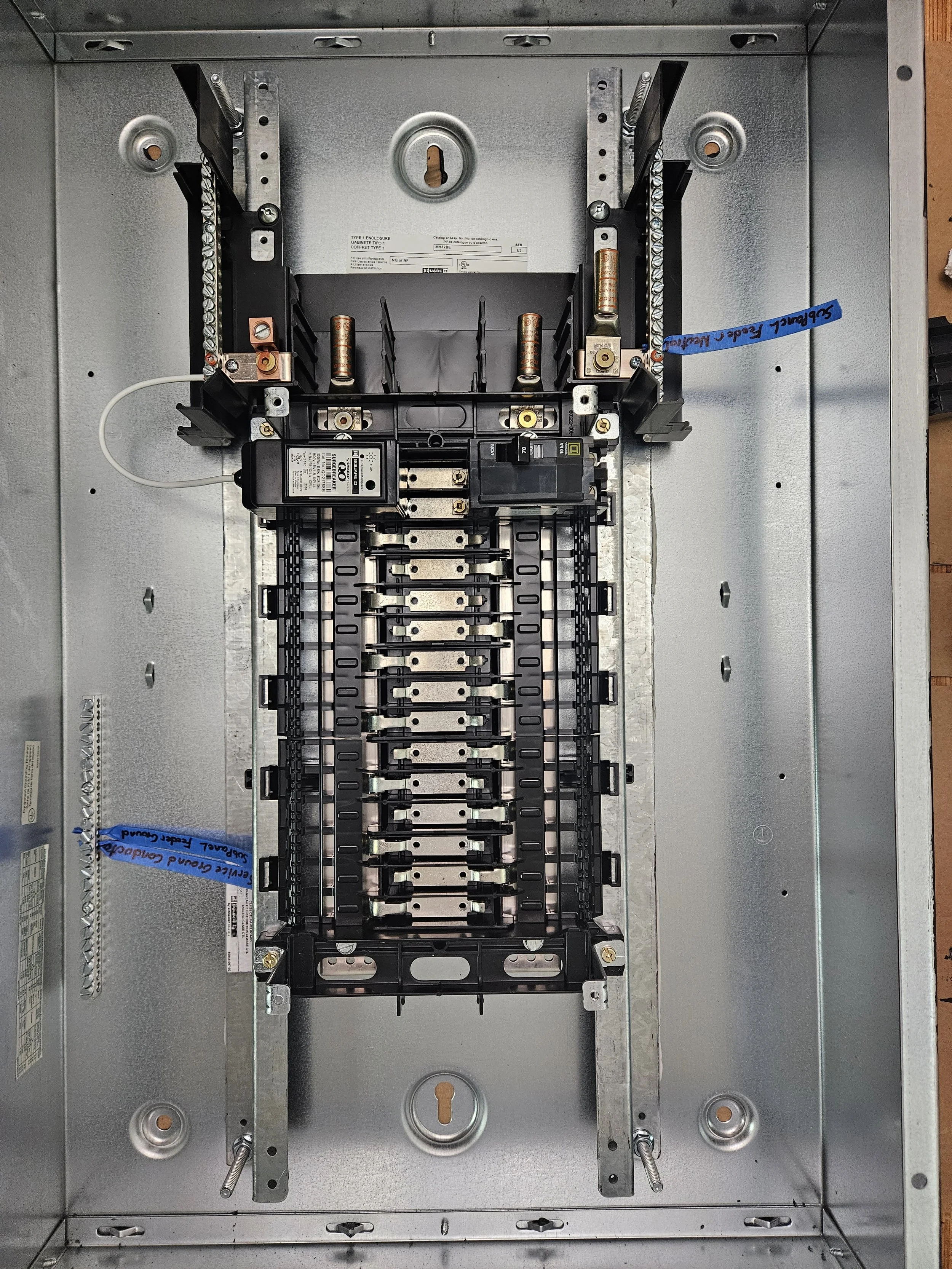

We offer what I consider to be the most premium panelboard available. The base of this panel is a Square D 225 Amp copper bus 30 or 42 space NQ interior. I order the panels special with Silver plated copper phase bus and copper grounds and neutrals.

When thinking about noise, these panels stock are far from perfect. They are dirty and have pretty rough contact surfaces. I offer an additional service to strip these panels to their core, clean them, then reassemble. I pay extreme attention to detail. I break these panel down to their most basic parts, clean, polish to a bright shine, wash, and contact enhance every surface. I provide Ilsco long barrel industrial copper compression lugs that are also, cleaned, polished and contact enhanced. These panels when configured correctly, are very high in performance. These panels accept bolt on and plug on circuit breakers. They can be configured with affordable snap on QO AFCI breakers to meet code.

Panelboards can be rated up to 600 Amps.

Panels can be 18, 30 or 42 space.

Pricing 225A = $2250 with Copper mechanical lugs. Plus breakers and SPD. Pricing 100A = $2450 with copper mechanical lugs. Seems odd its more, but the lugs are $550 my cost. Plus breakers and SPD.

I have a variety of MLO all copper NQ panelboards in stock. These are by far the best and most economical panel to act as the primary distribution panel or subpanel in a residence.

Comparison of QO loadcenter vs NQ panelboard interior.

NQ panelboard 100A and 225A phase bus, neutral and ground use the same gauge materials. 1.5” x 1/8” phase bus bar. These are big bars. Over 50% larger and far more conductive plating than the tin plated bars on a loadcenter.

200 QO loadcenter phase bar is 15/16” x 1/8”. 125 A QO loadcenter phase bar is 5/8” x 1/8”.

Also note the bus on the NQ panel is silver plated. The bus on the QO is tin plated.

Electrical conductivity of Silver is 105. Copper is 100. Aluminum is 61. Tin is 15.

I order or configure the NQ panels with copper components. I polish every copper to copper contact and use corrosion reducing/contact enhancement on all surfaces. This is by far the most effective means to remove a sleigh veil I believe occurs do to the galvanic reaction of the copper/aluminum interface. As well as oxidation damage.

Custom panelboards, Utility Service Equipment as well as 120 volt only Torus Isolation transformer distribution - Custom panelboards are just that. They are custom through and through. Our custom panels are manufactured for us utilizing heavy gauge copper bars. The cans are heavy gauge welded steel. They are built to full industrial standards and will outlive the home they are put in. They are dense, heavy, damp vibration well and are an excellent low impedance source of power for hungry high wattage amplifiers. Custom panels can be configured with a variety of circuit breakers. Custom panel covers are available in a variety of powder coat colors.

A significant benefit to custom panels is they can be built and fully UL listed and labeled for 120 volt only. This is the only panel in the USA and Canada that can accept a 100A single 120 volt output from a very large wall mount Torus Isolation transformer. I very much like to configure a Torus/Distribution as a single core. This panel allows for that. I will explain more why under the Torus page.

Custom panels are designed to exceed any panel available through normal electrical distribution channels. They are designed and built from the ground up by a UL accredited electrical manufacturing plant in the USA. Custom panels are centered around extremely heavy, density rated copper bus bar (¼” x 1”-1.5”). The bussing can be bare copper or silver coated copper. The circuit breakers are Eaton bolt on BAB/QB breakers available with or without AFCI protection. These panels are mounted in custom heavy gauge welded seam 14.5” wide x 4.5” deep cans that are a direct fit in standard residential 2x6 wall stud spacing. No framing changes required. If space allows we prefer to use a 20” wide can. Much better working space. These panels can be configured as a main distribution panel or subpanel.

Contact me for pricing. Custom panels are generally around $5500

Custom panels are a 3 week lead.

Where is the biggest bang for my buck.

I would not advocate removing a perfectly good loadcenter in my home to replace it with a panelboard in search of sonics.

If I were to be remodeling a home and the electrical service were being changed, I would absolutely use a NQ paneboard.

If I were to be adding a subpanel, I would use a NQ panelboard.

If I had a good service but really wanted to step up my audio performance, I would very much consider a Torus Isolation transformer.

If I added a isolation transformer and had multiple branch outlets around the room, I would consider a large single core high output isolation transformer followed by a panelboard to distribute the loads.